Introduction to the Winkelbohrspindel

The term Winkelbohrspindel may sound highly technical at first glance, but within the world of machining and industrial manufacturing, it represents a tool that quietly solves some of the most frustrating production challenges. Translated from German, Winkelbohrspindel essentially refers to an angle drilling spindle, a specialized attachment or spindle unit designed to drill or machine at angles that standard vertical or horizontal spindles simply cannot reach.

In modern manufacturing, efficiency is no longer just about speed; it’s about flexibility, accuracy, and reducing unnecessary setup changes. This is where the Winkelbohrspindel shines. It allows manufacturers to perform complex drilling and milling operations without repositioning the workpiece, saving time while maintaining precision. As production demands grow more complex, the importance of such adaptable tools continues to rise.

Another reason the Winkelbohrspindel has gained popularity is its compatibility with CNC machines. CNC technology thrives on repeatability and accuracy, and angle drilling spindles complement this perfectly by enabling multi-axis operations within a single setup. This synergy significantly improves workflow efficiency, particularly in high-volume or precision-driven industries.

This article takes a deep dive into the Winkelbohrspindel—what it is, how it works, where it’s used, and why it has become such a valuable asset in modern machining. Whether you’re an experienced machinist, a manufacturing engineer, or simply someone exploring advanced tooling solutions, this guide will give you a thorough and practical understanding of the subject.

What Is a Winkelbohrspindel?

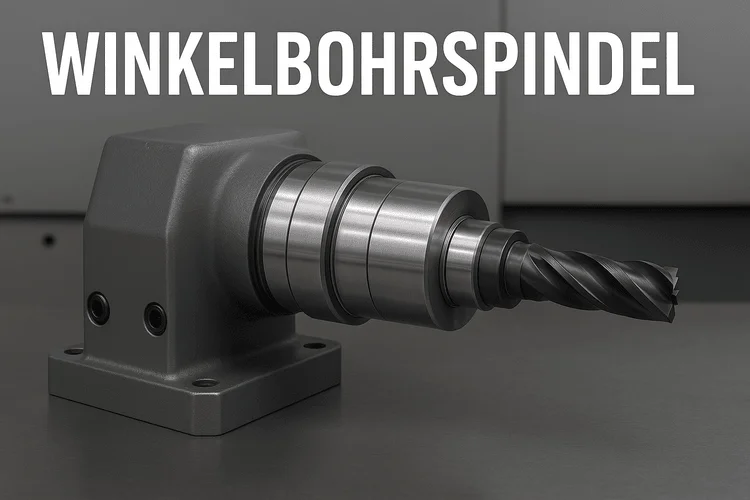

A Winkelbohrspindel is a mechanical spindle unit designed to redirect rotational motion at a specific angle, most commonly 90 degrees. Instead of drilling straight down or horizontally, it allows tools to operate sideways or at custom angles, making it possible to machine features that would otherwise require complex repositioning or additional machines.

At its core, the Winkelbohrspindel consists of a housing, internal gears (often bevel gears), bearings, and a tool holder. These components work together to transmit power efficiently while maintaining tight tolerances. Despite its compact size, this spindle attachment is engineered to handle substantial loads, torque, and rotational speeds.

What sets the Winkelbohrspindel apart from conventional spindle attachments is its precision engineering. The internal gearing is designed to minimize backlash and vibration, which is critical for maintaining surface finish and dimensional accuracy. This makes it suitable not only for rough drilling but also for high-precision applications.

Another defining feature is versatility. Winkelbohrspindeln are available in various configurations, including fixed-angle, adjustable-angle, and even multi-spindle variants. This flexibility allows manufacturers to tailor the tool to specific production needs, whether that involves drilling holes on the side of a component or machining complex internal features.

How a Winkelbohrspindel Works

Understanding how a Winkelbohrspindel operates helps explain why it is so effective in demanding machining environments. The spindle receives rotational power from the main machine spindle, typically through a coupling or direct mounting system. This rotational energy is then redirected via internal gears to drive the cutting tool at the desired angle.

Most Winkelbohrspindeln use high-quality bevel gears or spiral bevel gears. These gears are specifically designed to handle angular power transmission with minimal energy loss. Precision machining and heat treatment of these gears ensure durability and consistent performance even under heavy loads.

Bearings play a crucial role in the operation of the Winkelbohrspindel. High-precision bearings support the rotating components, reduce friction, and maintain alignment. Poor bearing quality would result in vibration, heat buildup, and reduced tool life, which is why premium spindles invest heavily in bearing technology.

Cooling and lubrication systems are another important aspect. Many Winkelbohrspindeln feature internal lubrication channels to ensure smooth operation at high speeds. Some advanced models also integrate coolant delivery directly through the spindle, improving chip evacuation and extending tool life during deep or angled drilling operations.

Types of Winkelbohrspindel Designs

Winkelbohrspindeln come in a wide range of designs, each suited to specific machining requirements. The most common type is the fixed-angle Winkelbohrspindel, usually set at a 90-degree angle. This design is ideal for side drilling, cross holes, and perpendicular milling operations.

Another popular design is the adjustable-angle Winkelbohrspindel. These models allow the user to set the drilling angle within a defined range, offering greater flexibility for complex geometries. While slightly more complex in construction, adjustable models are invaluable for custom or low-volume production runs.

Multi-spindle Winkelbohrspindeln are designed for high-productivity environments. These units feature multiple tool outputs, enabling simultaneous drilling of several holes at once. This design is especially common in automotive and mass-production industries where cycle time reduction is critical.

There are also custom-engineered Winkelbohrspindeln built for specific applications. These may include extended housings, reinforced gear systems, or unique mounting interfaces. Although more expensive, custom solutions often deliver unmatched performance in specialized production scenarios.

Key Components and Materials Used

The performance and longevity of a Winkelbohrspindel depend heavily on the materials used in its construction. The housing is typically made from hardened steel or high-strength aluminum alloys, providing a balance between durability and weight reduction.

Internal gears are usually manufactured from alloy steel and undergo precision grinding and heat treatment. This ensures high load capacity and resistance to wear, even during continuous operation. Gear quality directly affects noise levels, vibration, and overall efficiency.

Bearings are another critical component, often sourced from premium manufacturers. Angular contact bearings or ceramic hybrid bearings are commonly used in high-performance Winkelbohrspindeln to handle axial and radial loads simultaneously.

Tool holders and interfaces are designed to meet industry standards such as HSK, ISO, or BT. This compatibility allows seamless integration with existing tooling systems and CNC machines, reducing setup time and complexity.

Applications of Winkelbohrspindel in Manufacturing

One of the main reasons Winkelbohrspindeln are so widely used is their versatility across industries. In the automotive sector, they are essential for drilling side holes, oil channels, and mounting features in engine blocks and transmission housings.

In aerospace manufacturing, precision is everything. Winkelbohrspindeln enable the machining of complex components with angled holes and features while maintaining strict tolerance requirements. This reduces the need for multiple setups, improving consistency and reducing error risk.

The furniture and woodworking industry also benefits from angle drilling spindles. They allow precise dowel holes, concealed joints, and angled fastener placement, improving both structural integrity and aesthetics.

Even in general metal fabrication, Winkelbohrspindeln are invaluable for producing brackets, frames, and enclosures with side holes or internal features that would otherwise require additional equipment or manual intervention.

Advantages of Using a Winkelbohrspindel

One of the most significant advantages of a Winkelbohrspindel is reduced setup time. By allowing angled operations in a single machine setup, manufacturers can eliminate multiple repositioning steps, leading to faster production cycles.

Another major benefit is improved accuracy. Fewer setups mean fewer opportunities for alignment errors. This results in better dimensional consistency and improved overall part quality, especially in precision-critical industries.

Winkelbohrspindeln also contribute to machine utilization efficiency. Instead of investing in additional machines or fixtures, manufacturers can expand the capabilities of existing CNC equipment, maximizing return on investment.

From a long-term perspective, these spindles can also reduce tool wear and operator fatigue. Automated angle drilling minimizes manual handling and ensures consistent cutting conditions, which helps extend tool life and improve workplace safety.

Limitations and Challenges

Despite their many advantages, Winkelbohrspindeln are not without limitations. One common challenge is space constraints. The spindle attachment adds length and bulk to the machine setup, which can limit access in tight machining areas.

Another consideration is power transmission efficiency. While modern designs are highly efficient, angular gear systems inherently introduce some energy loss compared to direct-drive spindles. This must be accounted for when selecting cutting parameters.

Maintenance is another factor. Winkelbohrspindeln require proper lubrication and periodic inspection to ensure long-term reliability. Neglecting maintenance can lead to premature wear of gears and bearings.

Finally, there is the initial cost. High-quality Winkelbohrspindeln are precision tools and can be expensive. However, when evaluated against productivity gains and reduced setup times, the investment often pays for itself.

Choosing the Right Winkelbohrspindel

Selecting the right Winkelbohrspindel starts with understanding your application requirements. Factors such as spindle speed, torque, cutting forces, and available machine space all play a role in determining the ideal model.

Compatibility with your CNC machine is also critical. This includes mounting interfaces, tool holder standards, and control system integration. Ensuring proper compatibility minimizes installation issues and maximizes performance.

It’s also important to consider the type of materials you’ll be machining. Harder materials require robust gear systems and high-quality bearings, while lighter applications may prioritize speed and flexibility.

Working with reputable manufacturers or suppliers can make a significant difference. Established brands often provide better documentation, technical support, and customization options, ensuring long-term satisfaction and reliability.

Maintenance and Care Best Practices

Proper maintenance is key to maximizing the lifespan of a Winkelbohrspindel. Regular lubrication is essential to keep gears and bearings operating smoothly. Many modern spindles include automated lubrication systems, but manual checks are still important.

Routine inspections should focus on signs of wear, unusual noise, or increased vibration. Addressing minor issues early can prevent costly downtime and repairs later on.

Cleaning is another often overlooked aspect. Chips and coolant residue can accumulate around the spindle housing, potentially affecting performance. Keeping the unit clean helps maintain thermal stability and operational accuracy.

Finally, proper storage when not in use is crucial. Storing the Winkelbohrspindel in a clean, dry environment protects it from corrosion and accidental damage, ensuring it’s ready for use when needed.

Future Trends in Winkelbohrspindel Technology

As manufacturing continues to evolve, so does Winkelbohrspindel technology. One emerging trend is the integration of smart sensors that monitor temperature, vibration, and load conditions in real time.

Another development is the use of advanced materials, such as lightweight composites and ceramic bearings, to improve performance while reducing weight and heat generation.

Customization is also becoming more common. Manufacturers increasingly demand spindle solutions tailored to specific production challenges, driving innovation in modular and configurable designs.

Looking ahead, the combination of Winkelbohrspindeln with advanced CNC automation and digital manufacturing systems promises even greater efficiency, precision, and flexibility.

Conclusion

The Winkelbohrspindel is far more than just an accessory; it is a powerful tool that expands the capabilities of modern machining systems. By enabling precise angled operations within a single setup, it helps manufacturers save time, improve accuracy, and enhance overall productivity.